AUTOTRANS SYSTEMS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AUTOTRANS SYSTEMS

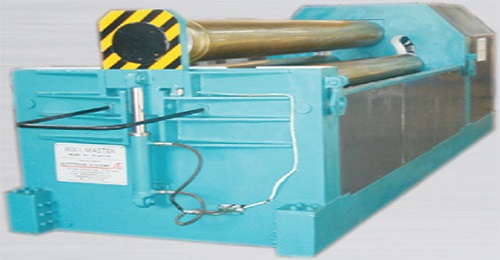

Roll Variable Axis Bending Machine

As the name indicates the variable axis plate bending machine have all 3 rolls which changes its axis as per rolling needs. The top roll moves up and down and both side rolls move in and out horizontally giving advantage of reducing bottom roll centre to form small diameter and medium thickness shell rolling and also by increasing bottom roll centre one can roll large diameter and heavy thickness shell. The another main advantage of machine is that the working height is much less compared to 3 roll/4 roll planetary axis machine. Also mac hine up to capacity of 50 mm plate bending may not need any foundation. The variable axis machine can also work as a press for plate straightening application and is also capable to roll conical shapes to almost 80% values that of machine specified capacity by using it as press.

Standard Featues

All 3 rolls can be inclined on both the side

Top roll positively driven through directly mounted gear box and hydraulic motor

Hydraulic brakes for bottom rolls to avoid any slippage of material while rolling

All rolls are mounted in heavy duly ball bearings

Heavy duty reinforced steel frame duly stress relieved and epoxy painted

Roll parallelism maintained by use of proportional valves and specially developed hydraulic system.

Heavy duty travelling central roller support

Automatic force lubrication

Optional Features

All 3 rolls can be positively driven

Automatic roll speed compensation

Induction hardened rolls hardness up to 52-55 RC

Conical bending device for small reduced side bending/ rolling

Advantages

Plate material is always horizontal which makes it safe to work with this type of machine.

Lower working height due to different type of machine working principle

No need of machine foundation up to 50 mm plate rolling

Cone bending capacity is up to 80 % of banding capacity by shift and press method and since all three rolls are tilting rolls.

The top roll works as a press which enables plate straightening also

Due to machine geometry it is possible to roll higher capacity material by increasing bottom roll centre distance

Application

Railway: water tank, tankar, coach bogie wall profile bending/rolling

Automobile: silencers, fuel tanks, mufflers

Offshore: drill rings

Storage: silos,tanks

General engineering: Pressure vessal,boiler, tanks, piping, filter body

Earth moving: Excavator bucket, road roller drum, mobile compactors

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.